一、特點Characteristic

1.收放卷均采用雙工位電動翻轉結構;,實現不停機接料.

2.烘箱:上風機和下風機連體.以及抽風風機,均采用離心式大風機.(外貼小烘箱)

3.印刷壓輥采用雙氣缸壓印,用電磁閥控制壓輥的升降

4.重型穩定氣動油墨刀架:刮刀可任意調節上下和角度,橫向移動采用同步電機。

5.延長版的使用壽命。

6.裝版方式:氣頂無軸裝版.對版方式:齒輪箱離合氣動對版

7.套色系統:電腦縱向自動套色(可選帶靜止畫面),電腦可選科賽或普賽

8.印刷導輥直徑80mm,關鍵部位直徑90mm,導輥:臺資上海產導輥,鋁合金經過動、靜平衡處理

9.整機一體式墻板. 收卷2臺力矩電機,放卷2只(5公斤磁粉)

10.收、放料牽引張力和主電機采用日本安川變頻矢量控制,超低摩擦氣缸:日本騰倉(2只)

1.Reeling and unreeling by tumbling dual-station mechanism, realizing auto material change without machine halt.

2.Oven: wind turbine and fan conjoined. And convulsions fan, adopt the centrifugal fan.(attached with small oven)

3.Embossed printing roller adopts double cylinder, press roller is controlled by electromagnetic valve lift.

4. Heavy stable pneumatic ink knife: scraper can be adjusted to the upper and lower angle, the lateral movement of synchronous motor.

5.Extended service life.

6.Installation method: the top of the gas-free version of the plate. The method: gear clutch pneumatic version.

7.Register system: computer vertical automatic register(optional with static screen),computer can choice kesai or pusai.

8.The diameter of printing roller is 800mm, the diameter of key part is 90mm. Roller: is made of Shanghai(Taiwan investment), aluminum alloy treated with dynamic and static balance.

9.Whole machine integral wall plate. 2 torque motors of wind, 2 unwind(5kg magnetic powder)

10. Feeding and discharging traction tension and the main motor adopts Japan Yaskawa inverter vector control, ultra low friction cylinder: Japan Tengcang(2 pcs)

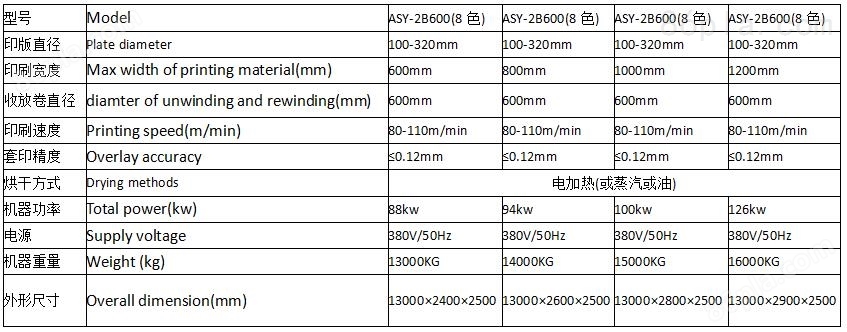

二、主要技術參數: Main technical parameter