產品介紹Product introduction

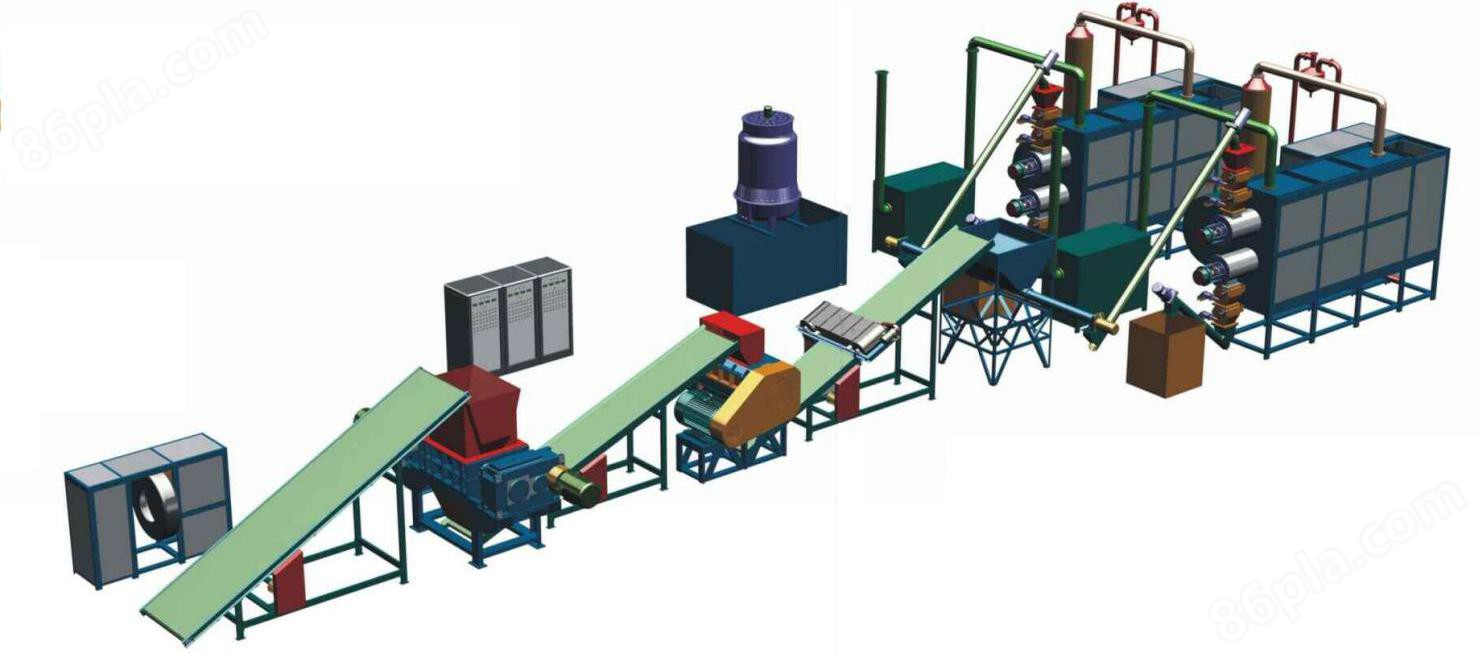

本項目采用常溫物理法對廢橡塑制品進行破碎、撕碎,利用常壓低溫裂化裂解反應。還原成液體燃料油后自動分離出燃料油、廢金屬、炭黑和少量的不不可燃氣體。全過程封閉生產、配備煙氣經凈化系統,無三廢排放、無二次污染,實現高效、節能、環保。全自動PLC 程序控制運行。

This project used physical method to shred and crush scrap rubber and plastic products in room temperature , and used low temperature pyrolysis reaction at normal pressure. After being reduced to liquid fuel oil, the scrap metal, carbon black and a small amount of non-flammable gas that are automatically separated. The whole process is closed production, equipped with flue gas purification system with no waste discharge, no secondary pollution,high efficiency, energy saving and environmental protection. Fully automatic PLC program control operation.

特點Features

的常溫恒壓供熱重組工藝方式,實現了動態供應和靜態受熱,使被裂解物料受熱均勻,能精確地調節和自動控制 溫度,實現了熱能循環利用,熱效率高,節約能源,反應速度快。

The world's advanced science and technology process mode of constant temperature and pressure heating reorganization realizes dynamic supply and static heating, which makes the pyrolysis materials evenly heated,it can accurately adjust and automatically control the temperature, and realizes the thermal energy recycling, high thermal efficiency, energy saving and fast reaction.

特殊的低溫催化裂解重組工藝,可不使用低溫硫轉移催化劑的在較低的溫度下,裂解物質裂解。油品好產率高,油品

中不含膠質與瀝青。裂化裂解溫度高或低,設備內無結焦,炭黑質量好。

Special low-temperature catalytic pyrolysis and recombination process can pyrolysis substance at a lower temperature without using low-temperature sulfur transfer catalyst. Good oil yield is high, the oil doesn’t not contain gum and asphalt. The pyrolysis temperature is high or low, there is no coking in the equipment, and the quality of carbon black is good.

由于裂解溫度低,且受熱均勻,使安全性能與設備壽命極大提高。

Due to the low pyrolysis temperature and even heating that the safety performance and equipment lifespan are greatly improved.

自動連續化 24 小時生產,設備工作穩定,產量是其他設備 2-3 倍,油品好。

The equipment is automatic continuous 24-hour production,which is stable operation, the output is 2-3 times than other equipment and the good oil output.

裂解產生的氣體凈化成可燃氣,用于供熱系統,不屬外界能源。

The gas produced during the pyrolysis is purified into combustible gas, which is used in heating system and not belong to external energy.

煙氣凈化系統的逆反工藝,具有強大的吸附能力,吸附脫附速度快,可以除去煙氣中所有污染物:H2S、CO、SO2 、SO3 NO、NO2 、CS2 、NH3 等油類有機化合物及固體顆粒,使排放達到國家的排放標準。全自動連續化廢塑料廢舊輪胎裂解生產線,24 小時常溫常壓連續化大規模生產,具有的安全環保性能以及良好的社會效益和經濟效益。

The counter reaction process of the flue gas purification system has strong adsorption capacity and fast adsorption and desorption speed, which can remove all pollutants in the flue gas: H2S, Co, SO2, SO3,NO2,CS2,NH3 and other oil organic compounds and solid particles, so as to make the emission meet the national emission standard. Full automatic continuous waste plastic tire cracking production line, 24-hour continuous large-scale production at room temperature and atmospheric pressure, which has excellent safety and environmental protection performance as well as good social and economic benefits.

應用方向Application

裂解油Pyrolysis oil:

直接出售,燃料,蒸餾設備加工成柴油Directly sold,fuel,reprocessed into diesel by distillation equipment.

炭黑Carbon black:

直接出售,制磚,,利用磨粉機加工品質更高炭黑Directly sold,bricks production,reprocessed high quality carbon black by pulverizer,

鋼絲Steel wire:

直接出售Directly sold.