回轉(zhuǎn)滾筒干燥機

一、工作原理及應(yīng)用范圍介紹 Introduction of Working Principle and Scope of Application

需干燥的物料經(jīng)加料器輸送到回轉(zhuǎn)圓筒干燥機的進(jìn)料端。物料從較高一端加入,熱載體可由低端進(jìn)入與物料呈逆流熱交換形式;也可以設(shè)計為熱載體與物料并流進(jìn)入筒體內(nèi)。干燥筒體轉(zhuǎn)動,物料在重力作用下運行到較低的一端,濕物料在圓筒內(nèi)向前移動過程中,與熱空氣進(jìn)行傳熱傳質(zhì),從而達(dá)到干燥之目的,被干燥的物料從出料端送出。在圓筒內(nèi)裝有各種形式的抄板(抄板形式、結(jié)構(gòu)是依物料特性的不同而不同)其作用是把物料抄起來灑下,形成料幕,使物料與氣流的接觸表面增大,以提高干燥速率并促進(jìn)物料前進(jìn)。尾氣經(jīng)旋風(fēng)分離器將氣體內(nèi)所帶物料捕集下來。如需進(jìn)一步減少尾氣含塵量,可設(shè)置袋式除塵器或水浴除塵器除塵后排放。

回轉(zhuǎn)圓筒干燥機是一種連續(xù)處理大批量物料的干燥設(shè)備,廣泛應(yīng)用在各種散粒物料的干燥,現(xiàn)已發(fā)展到應(yīng)用于溶液及膏狀物料的干燥上。運轉(zhuǎn)可靠,操作彈性大,適應(yīng)性強,處理能力大,物料的適應(yīng)性強,現(xiàn)廣泛應(yīng)用于各行業(yè),如:

1. 化工、礦工、冶金等行業(yè):礦石、礦渣、煤、金屬粉末、粘土、硅藻土、高嶺土。

2. 農(nóng)業(yè)、飼料、肥料行業(yè):秸稈、牧草、樹葉、魚粉、玉米醬、淀粉渣、酒糟、藥渣、果渣、醬油渣、甘蔗渣、草炭、有機復(fù)合肥、污泥、水產(chǎn)品廢料、食品廠廢料、屠宰廠廢料、有機肥料、無機肥料、磷肥硫銨。

3. 對有特殊要求的粉狀、顆粒狀物料干燥。

4. 如各種結(jié)晶體、輕質(zhì)碳酸鈣、活性白土、磁粉、石墨、無機泥漿、陶土、石灰漿、礦石泥漿、磷礦渣、鋁廠赤泥。

5. 要求低溫干燥,且需要大批量連續(xù)干燥的物料。

The materials to be dried shall be conveyed to the charge end of rotary drum drier via the feeder. The materials shall be charged from the relatively high end, and the heat carrier can enter from the relatively low end to present a counter-current heat exchange form together with the materials; it also can be designed as heat carrier and materials entering into the drum in cocurrent flow. The drier drum rotates, the materials move to the relatively low end under the action of gravity, the wet materials conduct heat and mass transfer with heat air in the process of moving forward in the drum, thus to reach the purpose of drying, and the materials that have been dried will be delivered from the discharge end. The drum is installed with various types of shovelling plates (according to different characteristics of materials, types and structures of shovelling plates are different), which shovels and sprays the materials to form a materials curtain to increase the contact surface between the materials and the airflow to improve the drying rate and promote the materials moving ahead. The end gas catches the materials carried by air via a cyclone separator. If it is necessary to further reduce the dust content of end gas, a bag filter can be set up or dust shall discharged after dust is removed with a wet dust collector.

Rotary drum drier is a kind of drying unit for continuous processing of materials in large batches, which is widely used for drying for various granular materials. Now it has been developed for drying of solution and paste materials. With reliable operation, large operation flexibility, strong adaptability, large processing ability, and strong adaptability to various materials, now it is widely used in various industries, for example:

1. Chemical, miner and metallurgical industries: ore, slag, coal, metal powder, clay, kieselguhr and kaolin.

2. Agricultural, feed, fertilizer industries: straw, pasture, leaves, fish meal, corn sauce, starch residue, vinasse, herb residue, lees, medical, pomace, soy sauce residue, bagasse, peat, organic compound fertilizer, sludge, waste of aquatic products, waste of food factory, waste of the abattoir, organic fertilizer, inorganic fertilizer, phosphate fertilizer ammonium sulphate.

3. Drying of powdery and granular materials with special requirements.

4. Various crystalline solids, light calcium carbonate, activated clay, magnetic powder, graphite, inorganic mud, argil, lime slurry, ore slurry, phosphor slag and aluminum plant red mud.

5. Materials requiring low temperature drying and continuous drying in large batch.

二、特點Characteristics

1.干燥機處理能力大,燃料消耗少,干燥成本低,系連續(xù)不間斷的大批量的烘干裝置。

2.結(jié)構(gòu)簡單,操作方便 , 清掃容易。

3.故障少,設(shè)備維護費用低。

4.適應(yīng)范圍廣,可以用于處理顆粒狀物料與各種流動性相對比較好一點的物料的脫水烘干。

5.操作彈性大,可擴展能力強,產(chǎn)能適應(yīng)性強,即使產(chǎn)量小幅度增加,也無需更換設(shè)備。

1. With large processing capacity, less fuel consumption and low drying cost, the drier is a drying unit for continuously drying in large batch.

2. It is of simple structure, convenient for operation and easy to clean.

3. It has less troubles and low equipment maintenance costs.

4. It has wide scope of application , and it can be used for dehydration and drying of granular materials and various materials with relatively good liquidity.

5. With large operation flexibility, strong expandable ability and strong capacity adaptability, it is not necessary to replace the drying unit even if the output increases slightly.

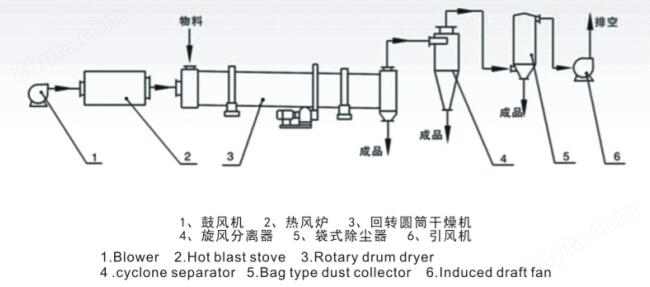

三、工藝流程圖 Process flow diagram

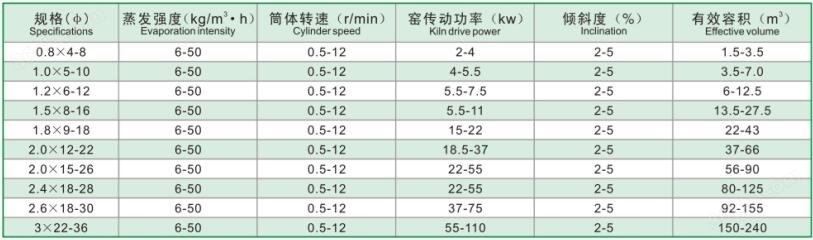

四、技術(shù)參數(shù)(下表中數(shù)值僅供選型時參考)

Technical parameters (the values in the table below are for reference in type selection only)

回轉(zhuǎn)滾筒干燥機組Rotary Drum Drying Unit回轉(zhuǎn)滾筒干燥機

| 參考價 | 面議 |

具體成交價以合同協(xié)議為準(zhǔn)

- 公司名稱四川川大干燥科技工程有限責(zé)任公司

- 品 牌

- 型 號

- 所 在 地成都市

- 廠商性質(zhì)其他

- 更新時間2023/7/27 9:15:19

- 訪問次數(shù)97

四川川大干燥科技工程有限責(zé)任公司(簡稱:川大干燥)是于2001年成立的一家集技術(shù)研發(fā)、技術(shù)轉(zhuǎn)讓、裝備制造加工的企業(yè)。川大干燥行政管理與設(shè)計研發(fā)部門設(shè)在四川大學(xué)科技創(chuàng)新中心大樓內(nèi);生產(chǎn)和試驗科研基地位于成都羊安鎮(zhèn)工業(yè)園區(qū)內(nèi),并獨自建設(shè)有加工制造中心與產(chǎn)品測試展演中心。公司從建立之初即著力科技研發(fā),重心即著力醫(yī)藥、食品等方面的工藝技術(shù)研究與*裝備的研制上。公司具有門類學(xué)科齊全的專業(yè)研發(fā)隊伍,所研發(fā)的產(chǎn)品品質(zhì)優(yōu)良、性能可靠、外形美觀;經(jīng)過近三十年的產(chǎn)業(yè)技術(shù)研究、產(chǎn)品技術(shù)研制、產(chǎn)出技術(shù)研驗,已具有獨立自主知識產(chǎn)權(quán)的工藝及配方生產(chǎn)技術(shù)三項;固體制劑系列裝備已研制有十二類近兩百種不同規(guī)格。而今川大干燥嚴(yán)格按照新版GMP精心研制的制藥與食品裝備無論是在技術(shù)性能上,還是在性價比上都處于同行前列。現(xiàn)“川大干燥”的產(chǎn)品與服務(wù)無論在中國還是在世界各國的制藥、食品、保健品、動物藥業(yè)等行業(yè)以及其它行業(yè)均享有盛譽,已經(jīng)形成特色與影響力的品牌。川大干燥除了在制藥與食品等行業(yè)提供良好技術(shù)服務(wù)與優(yōu)良產(chǎn)品以外,川大干燥還擁有包括工業(yè)粉塵凈化回收技術(shù)與系統(tǒng)工程裝備研制技術(shù)、大氣凈化環(huán)保工程裝備與家用PM2.5凈化器等系列產(chǎn)品技術(shù)。川大干燥向提供的優(yōu)良裝備產(chǎn)品有:各種烘干設(shè)備、各種造粒設(shè)備、各種混料設(shè)備、各種粉碎設(shè)備、各種篩分設(shè)備、各種滅菌設(shè)備、各種濃縮提取設(shè)備、各種環(huán)保設(shè)備等等。川大干燥向提供*的具有自主知識產(chǎn)權(quán)的工藝及裝備總包的項目有:l 雞精調(diào)味料工藝技術(shù)、工藝配方生產(chǎn)技術(shù),雞精調(diào)味料全套生產(chǎn)線。l 高品位高純度三偏磷酸鈉工藝生產(chǎn)技術(shù)以及生產(chǎn)線(川大干燥起草的三偏磷酸鈉國家標(biāo)準(zhǔn)已于2015年3月正式公布實施)。l 鮮榨提取制取方便型老姜湯沖劑工藝技術(shù)以及全套生產(chǎn)線等等。

真空干燥設(shè)備

回轉(zhuǎn)滾筒干燥機一、工作原理及應(yīng)用范圍介紹IntroductionofWorkingPrincipleandScopeofApplication需干燥的物料經(jīng)加料器輸送到回轉(zhuǎn)圓筒干燥機的進(jìn)料端

回轉(zhuǎn)滾筒干燥機組Rotary Drum Drying Unit回轉(zhuǎn)滾筒干燥機 產(chǎn)品信息

關(guān)鍵詞:干燥機

在找 回轉(zhuǎn)滾筒干燥機組Rotary Drum Drying Unit回轉(zhuǎn)滾筒干燥機 產(chǎn)品的人還在看