| 項(xiàng)目 | Item | 單位 | ZSH 170 | ||

| 注射裝置 | INJECTION UNIT | 主注射系統(tǒng) | 副注射系統(tǒng) | ||

| 螺桿直徑 | Screw diameter | mm | 45 | 30 | |

| 理論注射容量 | Shot volume(theoretical) | cm3 | 357 | 92 | |

| 注射重量 | Injection weight(ps) | g | 325 | 83 | |

| 注射速率 | Injection rate | g/s | 160 | 73 | |

| 注射壓力 | Injection pressure | Mpa | 177 | 170 | |

| 螺桿轉(zhuǎn)速 | Screw speed | rpm | 180 | ||

| 鎖模裝置 | CLAMPING UNIT | ||||

| 鎖模力 | Clamping force | kN | 1700 | ||

| 移模行程 | Open stroke | mm | 435 | ||

| 拉桿間距(寬×高) | Space between tie bars(W×H) | mm | 470×470 | ||

| 模厚 | Max.Mold height | mm | 520 | ||

| 最小模厚 | Min.Mold height | mm | 180 | ||

| 頂出行程 | Ejector stroke | mm | 140 | ||

| 頂出力 | Ejector stroke | kN | 50 | ||

| 其他 | OTHERS | ||||

| 油泵壓力 | Max Pump pressure | kW | 32 | ||

| 油泵電機(jī)功率 | Pump motor power | kW | 30 | ||

| 電熱功率 | Heating power | kW | 12.3 | ||

| 外形尺寸(長(zhǎng)×寬×高) | Machine dimension(L×W×H) | m | 5.40×1.30×2.05 | ||

| 油箱容積 | Olitank cubage | L | 300 | ||

| 機(jī)器重量 | Machine weight | t | 6 | ||

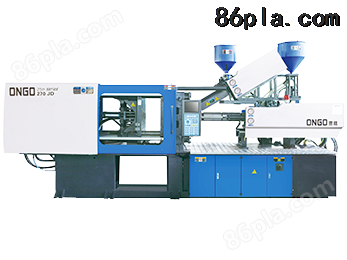

主射臺(tái)設(shè)在模板中線位置,而副射臺(tái)成一定的斜角,垂直安裝在主射臺(tái)上側(cè)。在占地面積不擴(kuò)大的前提下充分利用了空間位置。

Main injection unit is mounted in the center of the fixed platen. Side injection unit installs vertically upon the main unit with a certain oblique angle. It takes full advantage of space without occupying larger floor space.

主、副射臺(tái)可獨(dú)立控制,生產(chǎn)不同要求的混色產(chǎn)品。

Main injection unit and side injection unit can be controlled separately, and produce mixed color product as different requests.

主、副射臺(tái)可進(jìn)行不同規(guī)格的組合,滿足客戶的不同需求,實(shí)現(xiàn)夾層多物料成型。

There are various combinations of main injection unit and side injection unit with different specifications to satisfy customer’s needs and achieve sandwich injection molding with multimaterial.