一、單獨除濕機特點

小批量、連續的干燥是新一代光學產品*的*設備。

循環預熱空氣壓縮式除濕干燥設備在干燥時不用任何化學藥劑,可防止材料酸化、劣化、變黃等,不會污染筒內原料并清理容易。小批量、連續的干燥更可以保證原料的干燥效果,并防止原料對水分再吸收的可能性。運用真空方式達到快速干燥效果,縮短干燥時間、提高產能、節省能源為本機的優點,是新一代光學產品*的*設備。同時,其具有輕巧料筒設計,換料省時又省力,對于接單少量多樣訂單的業者而言,是生產的一大利器。

客戶獲得效益:

六倍干燥。與一般干燥系統比較,循環預熱真空式除濕干燥設備平均要快6倍左右。

節省能源。干燥時間縮短可提高產能外,還可節省能源60%。

空間更省。與一般除濕機搭配干燥機相比較,占用空間相對減少。

質量穩定。避免原料因長時間烘烤而產生變黃、變質的困擾。

節省成本。與一般除濕機相比較,耗材更為減少(免用干燥劑、蜂巢輪、冷卻水)。

安全智能。智能化操作接口,簡易方便,各種異常顯示增加檢修時的便利性,多重安全裝置確保用戶的安全。

Feature

The Best Drying Equipment for Optics Industry.

TAITIE BRAND Air Compression Type Dehumidifying Dryer works without any chemical to prevent resin from acidification, degeneration and yellowing. The easy-to-clean chamber design is environment friendly. The Air Compression Type Dehumidifying Dryer can shorten your drying time, increase your production, and save your energy and cost. The continuous drying in small batch dryer can ensure the dehumidifying quality and prevent the moist reversion. An Air Compression Type Dehumidifying Dryer is an indispensable drying equipment for optics industry.

With compact shortage tank design, easy to change materials and save time. As your order is small batch and various, it is the best choice for the order in small batch with various kinds.

Customer benefits

DRY FASTER. Air Compression Type Dehumidifying Dryer can dry resins six times faster than traditional kind.

SAVE ENERGY UP TO 60%. Vacuum drying technology can shorten the drying time and increase your productivity in order to save energy up to 60%.

SAVE SPACE. New design saves more space comparing a standard 3-in-1 dehumidifying dryer.

KEEP IN GOOD QUALITY. To avoid the degeneration and yellowing problems in long drying hours.

SAVE MONEY. Machine life time extension can save your money on spare parts such as desiccative or honeycomb wheels or cooling water.

USER-FRIENDLY CONTROL PANEL. The human machine interface control panel is user-friendly design with safety devices and abnormal signal indicators. With abnormal signal indicators, it is easy for operators to know which part has problems to fix or maintain.

二、單獨除濕機備注:

1以上列舉建議搭配干燥機與填料機之型號,將隨塑料等級、環境條件,需求不同等因素而調整。

2.若需更大機型,歡迎訂制。

3.如果單機一對多筒時,干燥風車加一級。

4.如遇到一對多干燥機必須適當加大除濕機機型或加大干燥機風車風量。

5. 如果輸送高度超過原規格時,請另選用適當的吸料系統 (配有抽空馬達吸料系統)。

6. 原料比重以0.65計算。

7.產品規格若有變更,恕不另行通知。

Remarks

1. To choose the suitable model of dryers and loaders will be changed by resin grade, drying condition and other factors.

2. Customized specification are available upon your early inquiry.

3. If your Dehumidifying Dryer works with more than one suction hopper, suggest to upgrade one level of your blower.

4. If your dehumidifying dryer apply for two more molding machines, we suggest you to increase the dehumidifying dryer’s size or enhance the fan flow of fan motor.

5. If the conveying height exceeds the specification, please choose a suitable autoloader with pipe cleaning device.

6. Specific Gravity: 0.65

7. We reserve the right to change the technical data without prior notice.

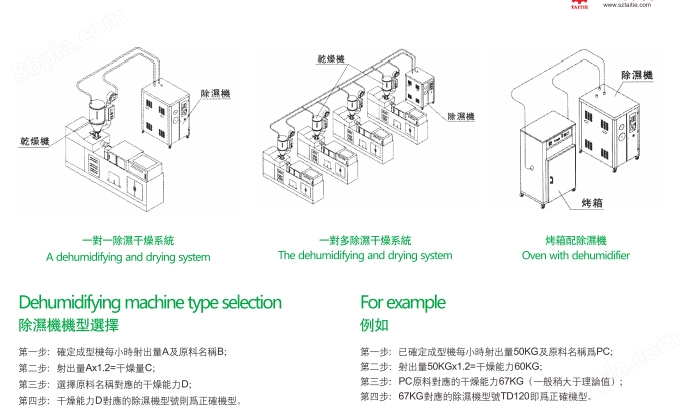

三、的連接圖